Conveyor Belt Weigher Manufacturers| Conveyor Belt Weigher Manufacturers in Chennai

Sharp Electronics have the honour of being among the most reliable and innovative manufacturers, suppliers, exporters, dealers, traders, and distributors of Conveyor Belt Weigher/ Belt Weigher / Belt Scale in Chennai. Being grounded in strong research foundations of decades of experience, technical knowledge, and dedication towards innovation, we have been providing weighing solutions that are precise as well as sensitive to the changing needs of new-age industries.

Our belt weighers use the best load cell technology, smart software integration, and IoT monitoring systems to offer accurate and reproducible measurement of material flow in real time. Right from the food processing business to mines, we have the right solutions to boost productivity, wastage reduction, and optimisation of operational efficiency.

Types of our Torque Sensor

One among the top Conveyor belt weigher/ belt weigher/belt scales suppliers in Chennai, we are offering the finest quality Conveyor belt weigher/ belt weigher/belt scales which include:

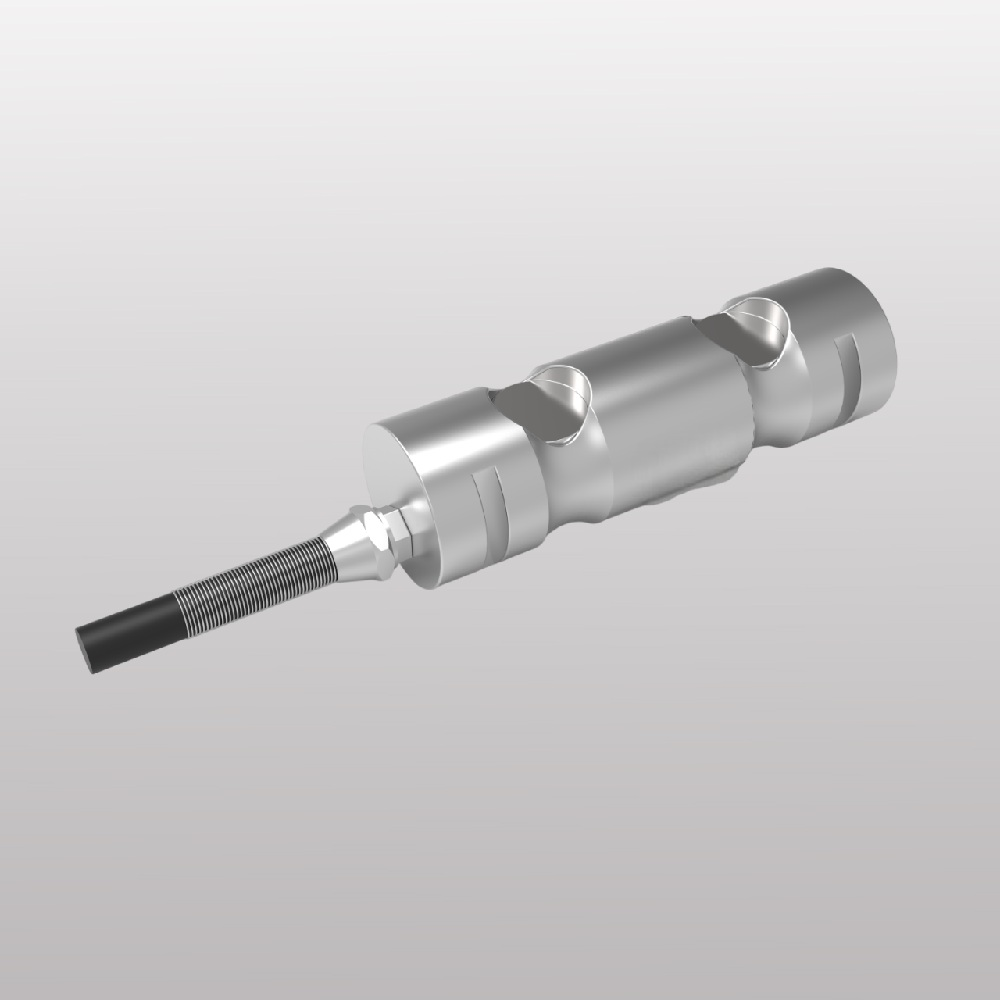

- Rotary Torque Sensors – Our rotary torque sensors are designed to measure dynamic and static torque with unmatched accuracy. Our sensors are designed to operate at high rotational speeds with no loss of performance. We also employ wireless transmission of data, and hence the operators can have real-time torque readings without the constraints of the conventional wired setup.

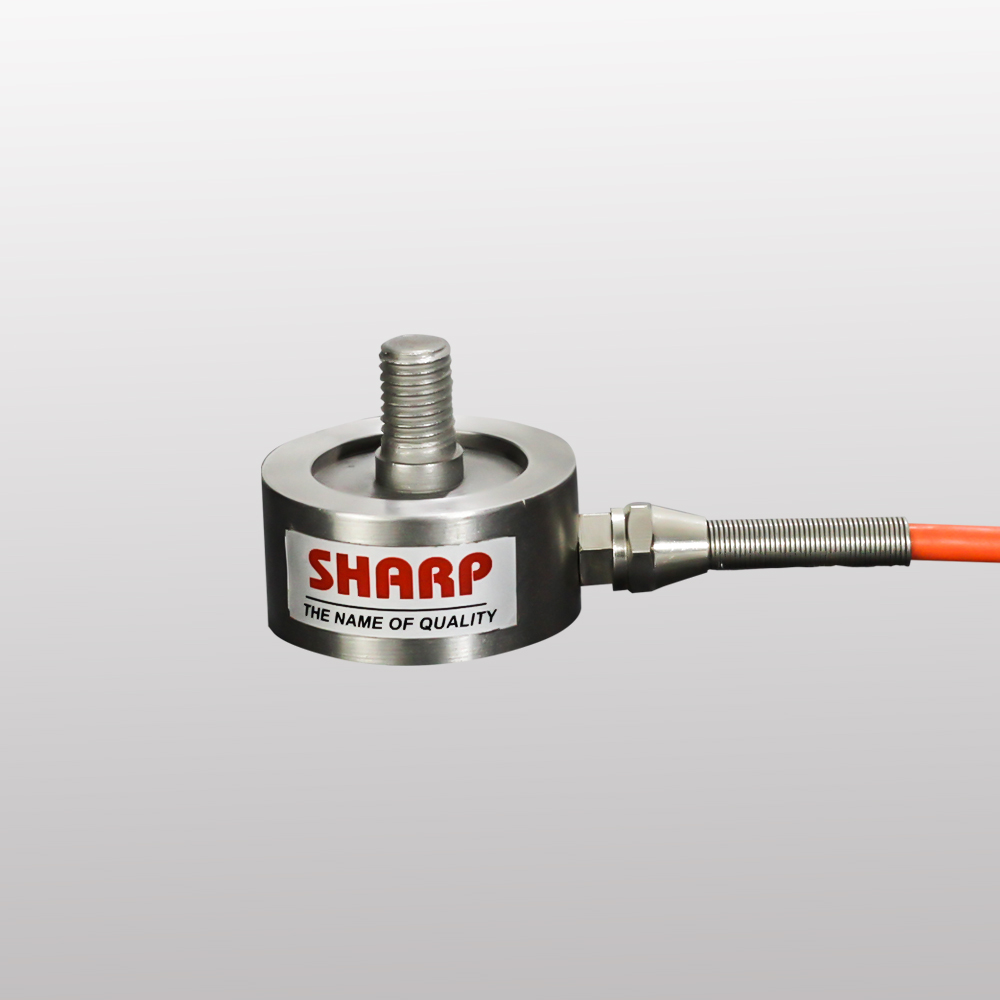

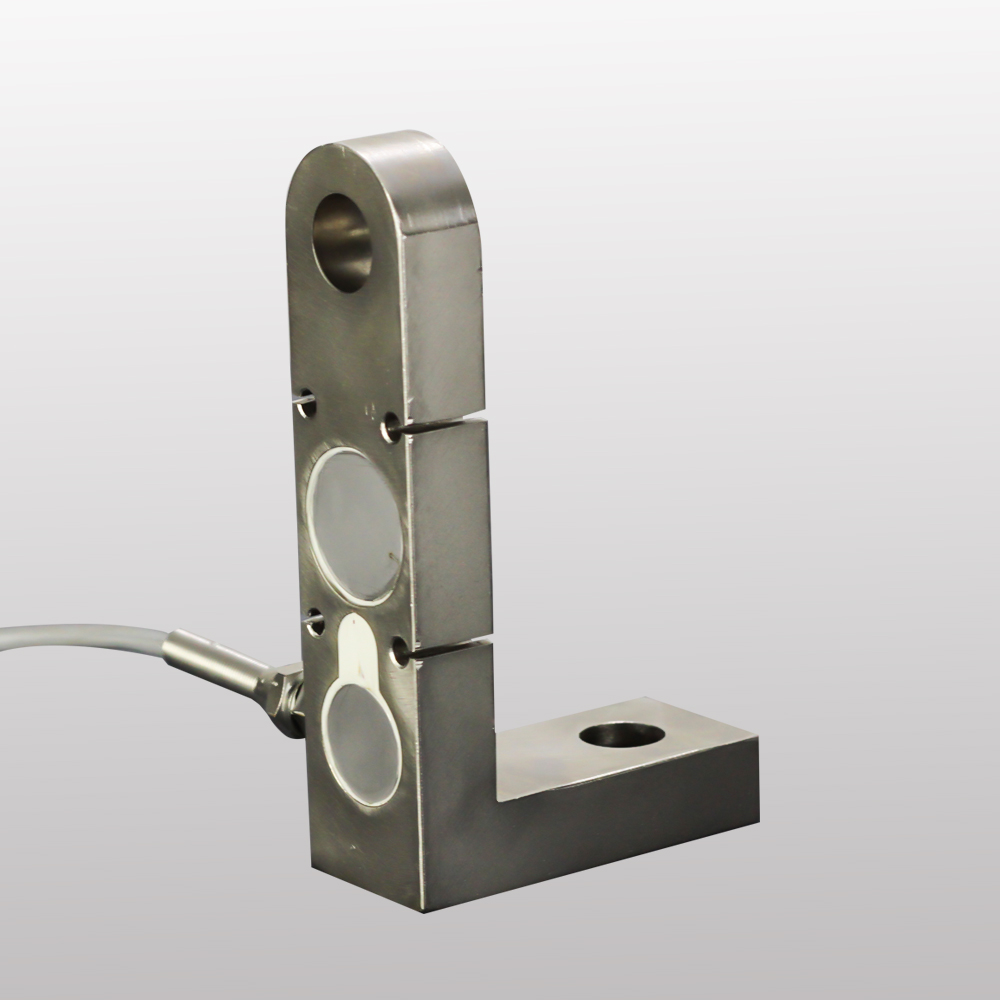

- Reaction Torque Sensors – Our reaction torque sensors are best used in cases where rotation is not employed but precise measurement of torque must be attained. They provide great stability and consistent results even during long work hours. We produce them from tough materials so that flexibility is never an issue under harsh industrial environments.

- Contactless Torque Sensors – We manufacture advanced contactless torque sensors based on non-contact signal transmission technology. This feature eliminates physical wear, which increases the working life of the sensor considerably. They are most ideally suited for constant use in machinery where maintenance downtime has to be reduced to the bare minimum.

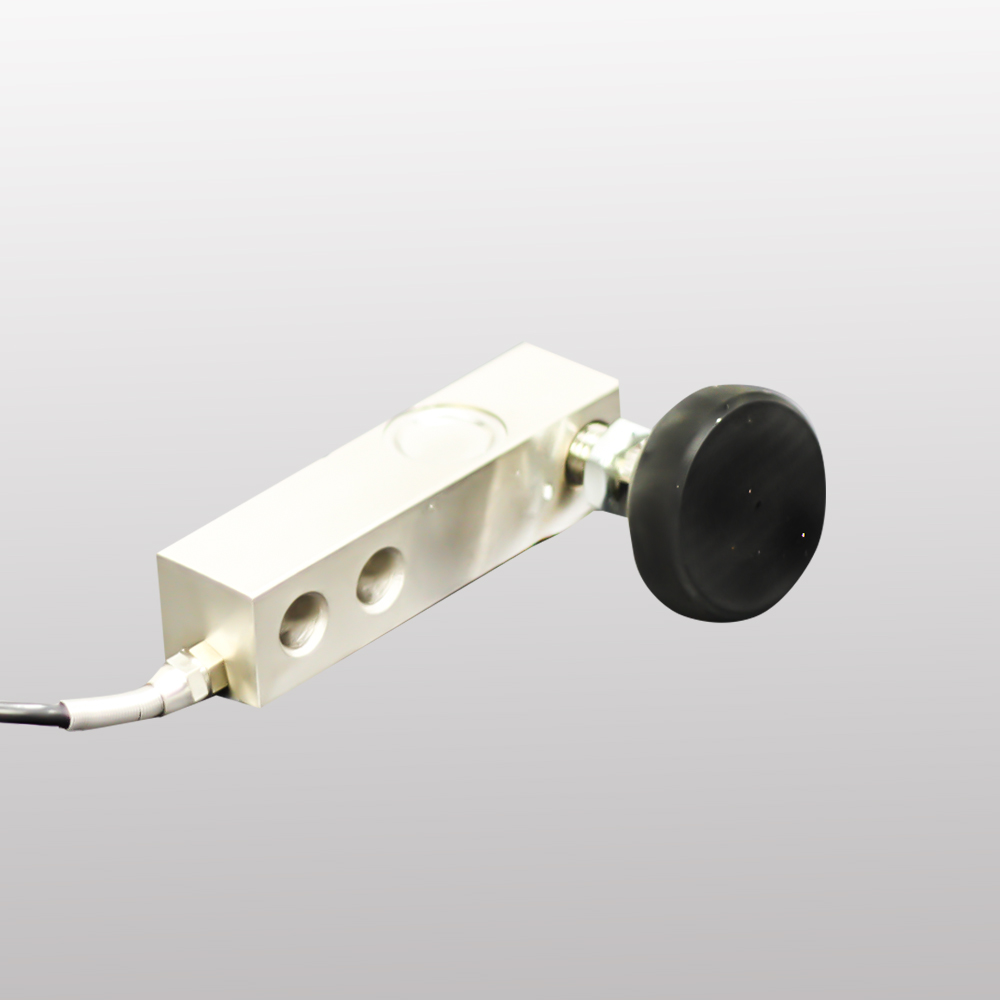

- Miniature Torque Sensors – We design miniaturized torque sensors with smaller sizes but sufficient accuracy. These are applied in robotics, precision equipment, and medical devices industries where there is limited space to conduct operations but accuracy are a priority. Their lightweight means it is easy to incorporate them without affecting the performance of equipment.

- Smart Torque Sensors – We produce smart torque sensors with IoT connectivity for intelligent monitoring solutions. The sensors facilitate predictive maintenance through real-time measurement of torque through internet-based platforms. With AI-driven analysis, industries benefit from faster and intelligent decision-making.

Technical Specifications

| Parameter | Specification |

|---|---|

| Weighing Capacity | 5 to 10,000 t/h (tons per hour) |

| Belt Width Range | 500 mm to 2,200 mm |

| Accuracy | ±0.25 % to ±1.0 % of totalized weight |

| Belt Speed Range | 0.1 m/s to 5.0 m/s |

| Load Cell Type | Strain gauge, stainless steel, IP68 protection |

| Number of Idlers | Single, dual, or multi-idler configurations |

| Output Signals | 4–20 mA, Modbus RTU/TCP, Profibus DP |

| Operating Temperature | –20 °C to +55 °C |

| Power Supply | 110–240 VAC, 50/60 Hz |

Features of our Conveyor belt weigher

One of the prominent Conveyor belt weigher/ belt weigher/ Belt scales suppliers in Chennai, our all-types of Conveyor belt weigher/ belt weigher/ Belt scales are filled with new technology formulations like:

- IoT & Cloud Integration for remote monitoring and predictive maintenance – We incorporate IoT technology in our belt weighers so that remote real-time monitoring is possible from any part of the world. Cloud connectivity makes it easier to store operational data and predictive maintenance so you can prevent downtime. This makes productivity higher and helps in long-term system performance.

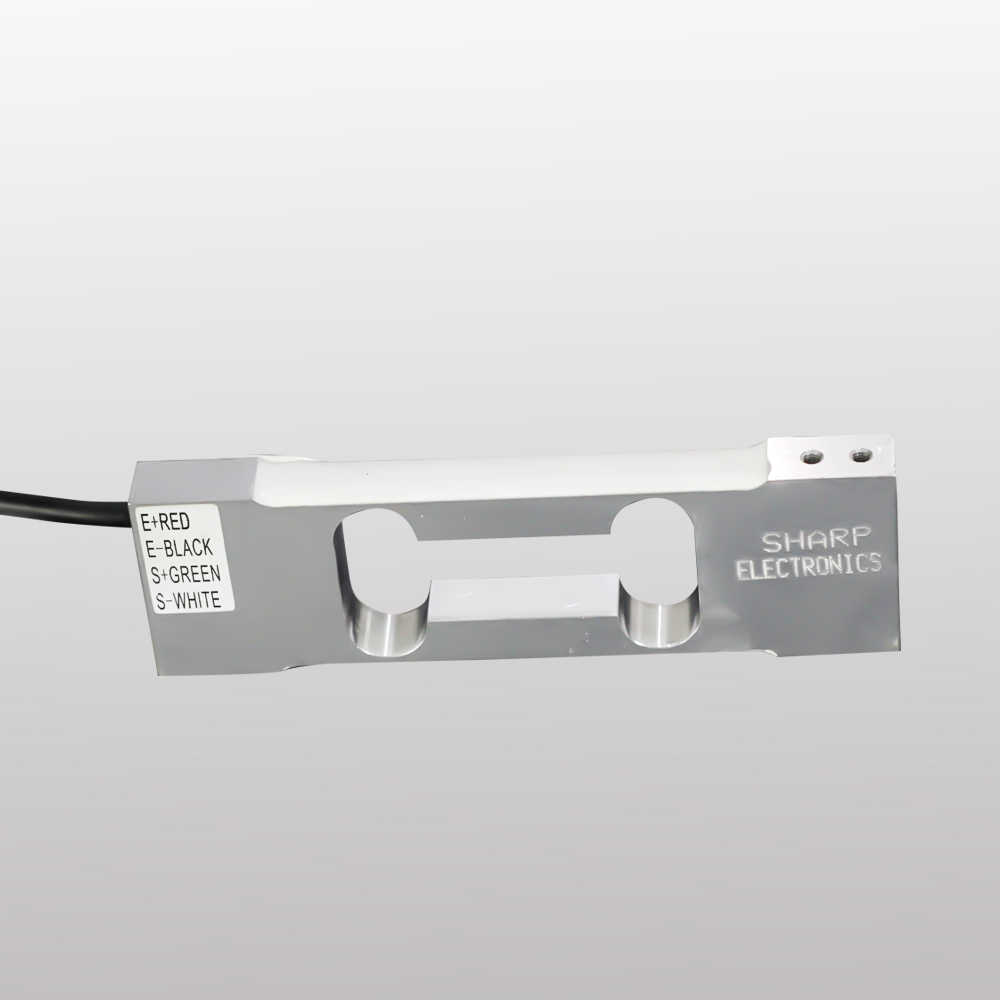

- High-Precision Load Cells with temperature compensation for exact consistency – Our load cells are compensated for any temperature state, thereby guaranteeing precision regardless of the environment. Our sensors have consistent output in even the most severe industrial environments. We take care that every load cell is calibrated before installation.

- Real-Time Data Processing with clear visual display and industrial-grade HMIs – We offer effective processors that offer real-time calculation support and data display. Operations are facilitated through other industrial-grade Human-Machine Interfaces (HMIs) by the operators. This assists in decision time reduction and control at the high level of operation.

- Self-Calibrating Mechanisms for reducing downtime and providing smooth performance – Our belt weighers automatically calibrate to provide optimum performance without human intervention. This reduces the time to conduct maintenance and ensures maximum operation efficiency. It also reduces human error in calibration procedures.

- Dust & Moisture Protection (IP65/IP67 rated) for heavy-duty industrial usage – Our enclosures are specifically designed to guard delicate parts from moisture and dust. This maximizes equipment lifespan and smooth operation under harsh working conditions. We guarantee that these levels of protection are in accordance with international industrial standards.

- AI-Based Analytics for optimizing throughput and abnormal detection of material flow – Our AI-driven software operates on data patterns so that abnormality in material handling can be detected. Operators can thus make such adjustments in a timely manner to avoid losses or inefficiency. It also supports high-end reporting for smart operation insights.

Benefits of our Torque Sensor

All such kinds of new conveyor belt weigher in Chennai provide different types of benefits like:

| Benefit | Description |

|---|---|

| Unmatched Accuracy | Ensures precise measurement to uphold product quality and process control. |

| Operational Efficiency | Provides precise and unbroken load measurements, enabling faster production cycles. |

| Less Wastage | Avoids overload and spillage, leading to raw material wastage savings. |

| Cost-Effectiveness | Reduces labour-intensive delivery with computerised results, leading to long-term cost savings. |

| Enhanced Safety | Live load monitoring technology prevents hazardous overloading conditions. |

| Scalable Integration | Highly integratable with minimal structural alteration, suitable for various applications. |

Applications of our Conveyor Belt Weigher

Being the exporters of Conveyor belt weigher/ belt weigher/Belt scales of India, our all types of Conveyor belt weigher/ belt weigher/ Belt scales are exported with new features and widely used in many applications including:

- Mining & Quarrying – We provide tough belt weighers that can withstand abrasive materials and high-throughput operations. They assist in precise monitoring to provide production levels without equipment overloading. They are designed to operate even in dusty and vibration areas.

- Cement & Aggregate Industry – Our solutions provide accurate batching and mixing of raw materials in cement and aggregate production. They provide consistent product quality and reduce waste to a minimum. The weighers can tolerate the heavy weight and heat that is typical in this industry.

- Food Processing – We offer belt weighers meeting food processing standards of hygiene and accuracy. They allow exact weighing of ingredients during processing and packaging. Safe operations are carried out with food-grade-compliant designs.

- Power Plants – Our belt weighers are used for monitoring coal feed rates in power plants to provide optimal boiler efficiency. Our measurement helps to reduce fuel burn and emissions. Our products have successfully operated in sustained high-load conditions.

- Agriculture & Fertilizer – We provide in-transit weighing of grains, seeds, and fertilizers solutions to maximise quality and reduce loss. The weighers can utilise bulk material with various densities. They are used in seasonal and continuous agriculture manufacturing.

- Ports & Logistics – Our belt weighers provide precise tracking of the movement of cargo in the import and export business. They can be interfaced with terminal management systems for improved control of flow. It enhances operation speed and minimises errors in billing.

- Recycling Plants – We provide belt weighers to ensure precise weighing of scrap and recyclables. They provide maximum pricing, sorting, and inventory management. Their durable build provides toughness in harsh recycling environments.

Sharp Electronics is leading Conveyor belt weigher/ belt weigher/belt scales manufacturers, suppliers, exporters, dealers, traders, and distributors in Chennai. We believe in providing the best conveyor belt weighing systems with ruggedness, precision, and the latest technology. We will surpass international quality standards and would be extremely careful to make sure that our products are designed specifically as per the requirements of Indian industries. Our dedication to product excellence, reliability, and overall customer satisfaction has established us as a partner of choice for Indian industry as well as others. Contact us today for more information!