Weighing Conveyor Manufacturers| Weighing Conveyor Manufacturers in Mumbai

Sharp Electronics is prominent weighing conveyors manufacturers, suppliers, exporters, dealers, traders, and distributors in Mumbai Our focus on quality, technology, and customer satisfaction has enabled us to offer world-class solutions to industries requiring precision material handling and measuring systems.

Weighing conveyor systems are a crucial part of industry automation today, merging the facility of conveyor systems with the accuracy of advanced weighing technology. Besides weighing products in real time, these systems deliver optimized production, reduced wastage, and greater control over operations. By steady R&D and implementation of the latest Industry 4.0 concepts, Sharp Electronics brings every weighing conveyor ahead of its time in performance and longevity.

Types of our Weighing Conveyors

Being a leading weighing conveyors suppliers company in Mumbai, we are providing excellent quality weighing conveyors such as:

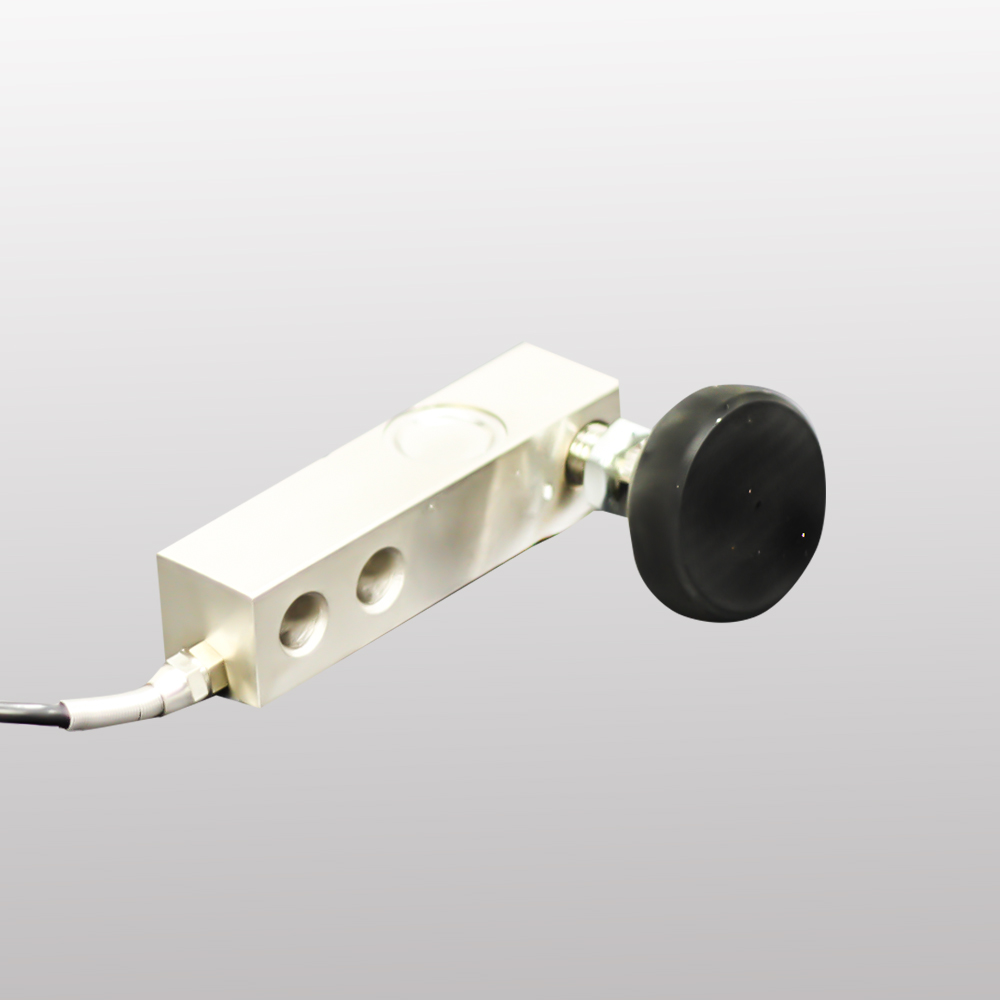

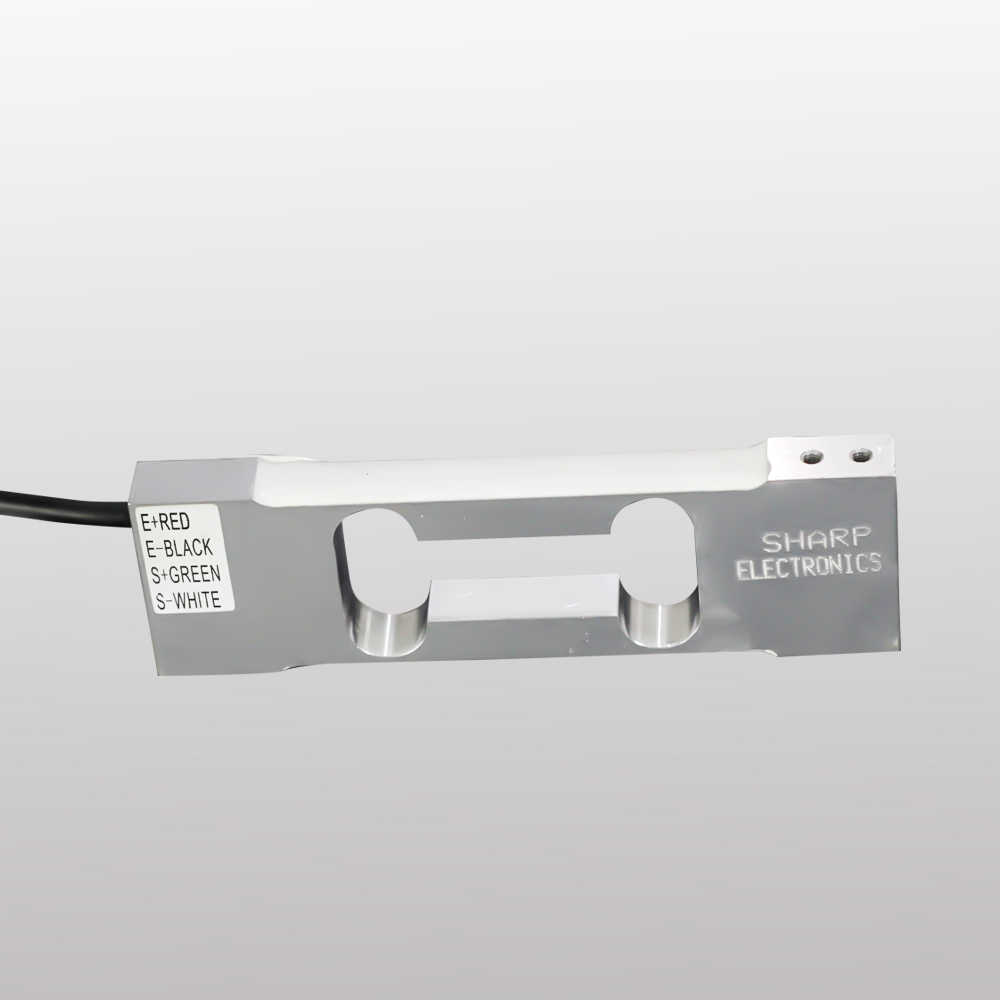

- Belt Weighing Conveyors – Our belt weighing conveyors are well designed to provide unparalleled accuracy in weighing bulk materials. Our latest machinery is equipped with intelligent load cell sensors that provide highly precise weight measurement as the material glides smoothly along the belt. They can be easily interfaced with plant data management software to facilitate real-time monitoring of performance. We also ensure that each belt conveyor is made for long-duration operation and low maintenance demand, hence it is a reliable choice for companies dealing with bulk material on a regular basis.

- Checkweigher Conveyors – We provide fast and accurate weight checks on packing lines using high-speed checkweigher conveyors specifically designed for this purpose. Our solutions feature auto-rejection capability, which rejects any product falling out of the pre-configured weight range automatically. Real-time performance can be accessed from anywhere by operators through IoT-integrated interfaces. Our solutions ensure product consistency, packaging productivity, and compliance with industry regulations.

- Portable Weighing Conveyors – We offer portable weighing conveyors that are lightweight yet robust enough to carry the requirements of operations that require mobility and versatility. They are wireless-capable, and weight information can be viewed by the operator from afar without workflow interference. Their compact design allows them to be utilised for temporary installations, seasonal production lines, or space-constrained areas. We have options for customization according to the varied requirements of various industries too.

- Inline Weighing Conveyors – We manufacture inline weighing conveyors to be incorporated directly into automatic assembly lines. Our sophisticated PLC controls enable smooth synchronization with other manufacturing processes so that bottlenecks are eliminated. The systems are engineered to continually monitor product weight without interrupting the production stream. Heavy-duty construction and easy maintenance components ensure they are able to run at high speed for extended periods.

- Heavy-Duty Weighing Conveyors – We produce heavy-duty weighing conveyors to endure harsh weights in demanding industries like mining, cement, and steel processing. We fit our conveyors with strong frameworks that can function even under harsh working conditions. The high-capacity heavy-duty weighing systems are developed to weigh high masses accurately to optimise the working process. Our models also have enhanced safety features to protect the equipment and workers.

Technical Specifications

| Parameter | Specification |

|---|---|

| Conveyor Type | Belt-based dynamic weighing conveyor |

| Belt Width (mm) | 600 – 1000 mm |

| Load Capacity (kg) | 5 – 150 kg per item |

| Conveyor Speed (m/min) | 10 – 90 m/min (variable frequency drive) |

| Weighing Accuracy | ± 0.05% of load |

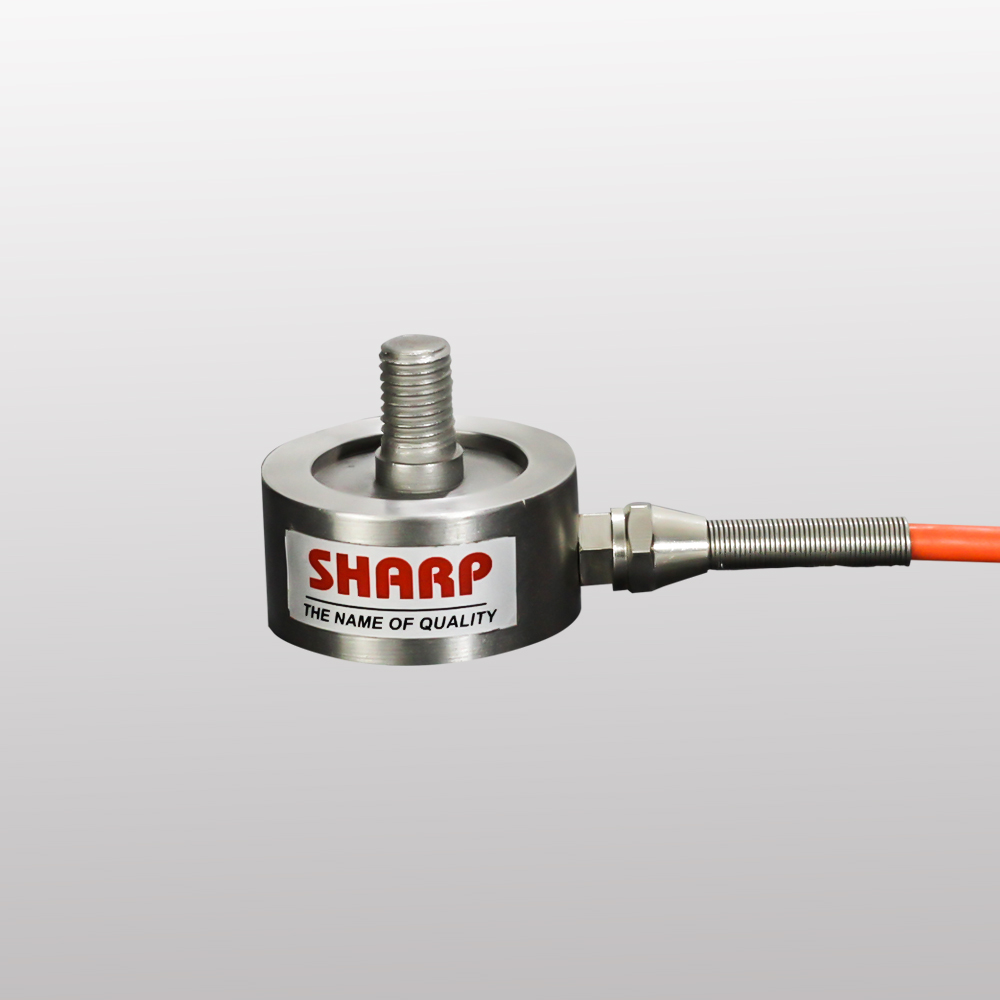

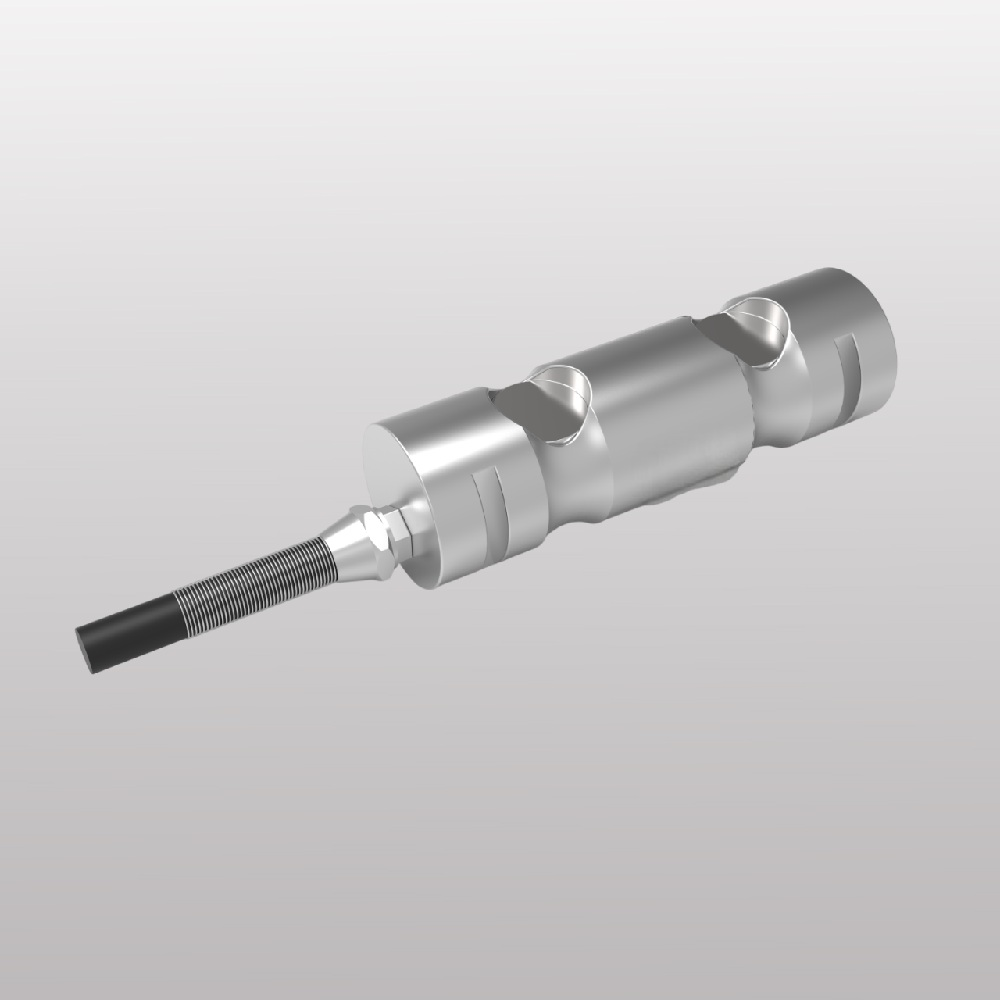

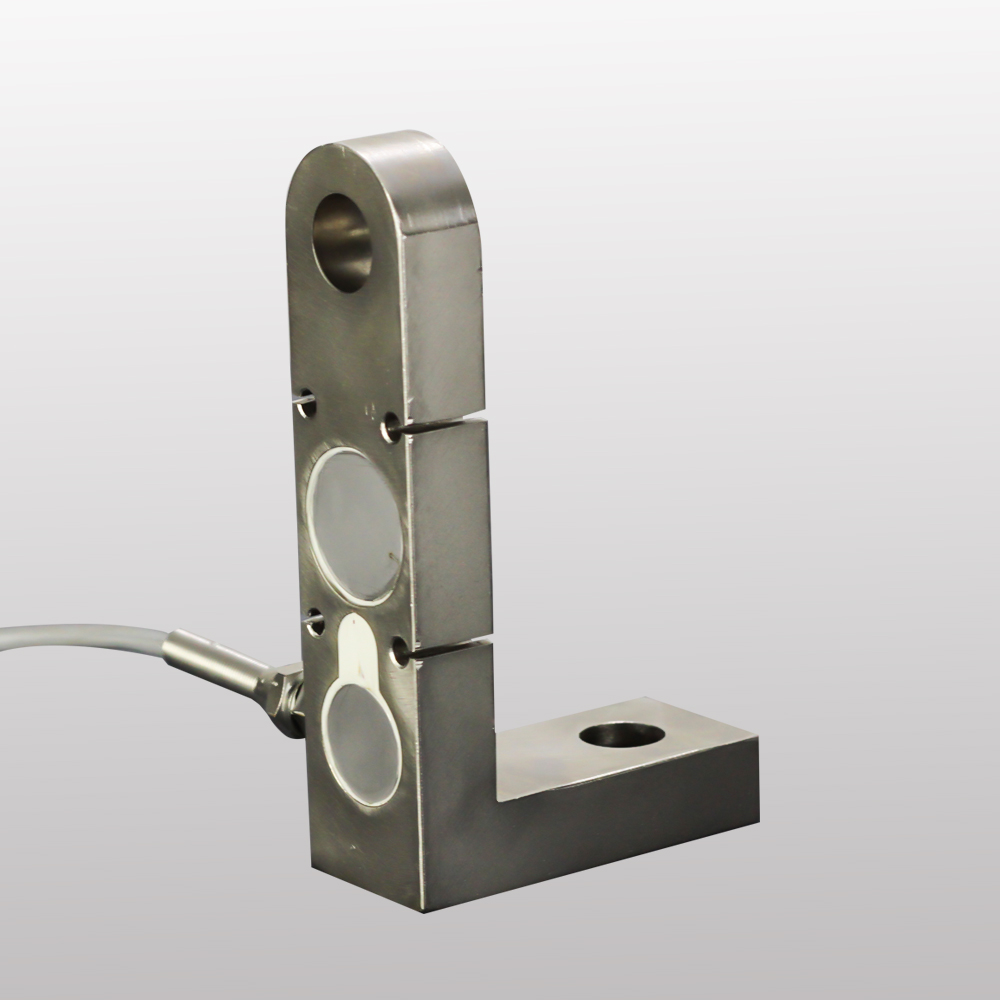

| Sensor Type | Strain gauge load cell, IP67-rated |

| Frame Material | Stainless steel AISI 304, powder-coated |

| Operating Temperature (°C) | -10°C to +45°C |

| Throughput Capacity | Up to 120 items/min |

Features of our Conveyor belt weigher/ belt weigher/belt scales

One of India's leading weighing conveyors dealers, our all-types of weighing conveyors are supplied with the latest technology formulas like:

| Feature | Description | Benefit |

|---|---|---|

| High-Precision Load Cell Technology | Self-calibrating load cell technology for consistent accuracy. | Ensures accurate measurements over time. |

| IoT & Cloud Connectivity | Real-time weight monitoring and preventive maintenance alerts. | Improves uptime and reduces repair costs. |

| Touchscreen HMI Panels | User-friendly interface for real-time parameterisation. | Maximises workflow efficiency and reduces training requirements. |

| Modular Design | Easy installation, expansion, and redesign. | Cost savings in installation and increased scalability. |

| AI-Based Analytics | Identifies production trends and efficiency losses. | Enhanced product consistency, quality, and resource utilisation. |

Benefits of using our Conveyor belt weigher/ belt weigher/belt scales

All these forms of new weighing conveyors that one can find in Mumbai offer various forms of advantages such as:

- Enhanced Accuracy – Eliminates human error while weighing with automated and real-time measurements. Each item gets weighed to perfection as they move down the conveyor using our systems, leaving no space for human error. This results in enhanced quality control and fewer customer complaints. Accuracy weighing companies notice massive improvement in production consistency.

- Productivity Boost – Automates production lines by combining conveying and weighing in one step. We minimise the need for independent weighing stations, conserving time and space. The combined system allows faster throughput and simple operations. Organisations notice their daily production boosted considerably without compromising on accuracy.

- Reduced Operating Costs – Ensures wastage is eliminated and follows precise application of material. We discourage industries from consuming surplus material by ensuring proper measurement of product weight. This automatically reduces cost on consumption of surplus raw material. In the long term, this benefit adds tremendous savings.

- Better Quality Control – Detects overweight or underweight products in real-time for regulatory compliance. Our conveyors detect out-of-spec product weight in real-time and remove defective products automatically out of the line. This ensures products meet regulatory and customer specifications. It also eliminates the risk of costly recalls.

- Smart Data Insights – Enables decision-making through the use of real-time and historical performance analysis. We provide solutions for the storage and analysis of performance data to identify areas where improvements should be addressed. The strategy based on data enables better operating decisions. Long-term performance tracking also contributes to strategic business planning.

- Increased Lifespan – Built with tough materials and rust-proof coatings for maximum lifespan. We produce conveyors with high-quality parts that withstand wear and tear. This results in them performing consistently during decades of usage. Our customers benefit from reduced replacement cycles and better return on investment.

Applications of our Conveyor belt weigher/ belt weigher/belt scales

Being India's exporters of weighing conveyors, all kinds of weighing conveyors are equipped with new features and are heavily used in various applications such as:

- Food & Beverage Industry – For accurate portioning, packaging, and compliance with food safety standards. We offer systems that ensure each food product weighs well above stringent requirements, which enhances the confidence of brands. Our conveyors are multi-functional and will transport various food products without infringing cross-contamination. They also have a smooth anodised finish to ensure they are easy to clean, as required by hygiene.

- Pharmaceutical Manufacturing – Proper dosage and package weight accuracy for drugs. We understand how critical it is to be exact with drugs. Our conveyors guarantee every package weighs exactly the same to comply with requirements. This avoids dosing discrepancies and keeps patients safe.

- Logistics & Warehousing – For inventory tracking and shipment verification. Our conveyors provide shipment weight verification to avoid billing errors. They also track the flow of inventory to improve stock management. This provides better visibility and fewer operational flaws.

- Mining & Minerals – Scales heavy volume materials like coal, iron ore, and aggregates. We provide conveyor belts that can take heavy-duty applications but still provide accurate weight measurement. This ensures equitable trade and accurate reporting. Our solutions also come with integration into bulk handling systems for trouble-free operation.

- Agriculture & Fertilizer Production – Accurate measurement of fertilizers, seeds, and grains. Our systems provide farmers and producers with accurate measurement of agricultural produce to prevent wastage. This means that resources are utilised efficiently and cost-effectively. Our conveyors can also be adjusted for fluctuation in seasonally varying production.

- Construction Material Handling – Cement, sand, and concrete handling with in-built weight monitoring. Our conveyors are made to handle heavy, abrasive construction material without a loss of performance. Accurate weighing gives accurate material mix ratios to help create uniform quality. These systems help construction companies provide efficiency on large projects.

Sharp Electronics is trusted weighing conveyors manufacturers, suppliers, exporters, dealers, traders, and distributors in Mumbai. Our load cells feature next-generation load cells, real-time monitoring of information, and IoT-based monitoring, allowing you to make data-driven decisions and receive real-time performance updates. Right from process control to inventory management, our solutions deliver consistency, compliance, and efficiency across.

We recognise that each industry is different, so we offer configuration options to suit your particular process requirements—whether you operate in the mining, food processing, manufacturing, logistics, or bulk material handling industries. We design our systems for minimum downtime, maximum throughput, and lower operating costs, so they are an excellent long-term investment. Contact us today for more information!