Torque Sensor Manufacturers| Torque Sensor Manufacturers in Chennai

Sharp Electronics is leading torque sensor manufacturers, suppliers, exporters, dealers, traders, and distributors in Chennai. Our Torque Sensors use sophisticated strain gauge technology, sophisticated signal processing, and long-lasting calibration systems to provide high accuracy, repeatability, and stability for industrial uses. They can provide exact torque measurement for rotating, stationary, and dynamic conditions and are therefore adaptable to use in industrial automation, robotics, electric mobility, wind turbines, aerospace, car test, and laboratories.

Types of our Torque Sensor

One of the most prominent Torque Sensor suppliers in Chennai, we are providing quality Torque Sensors such as:

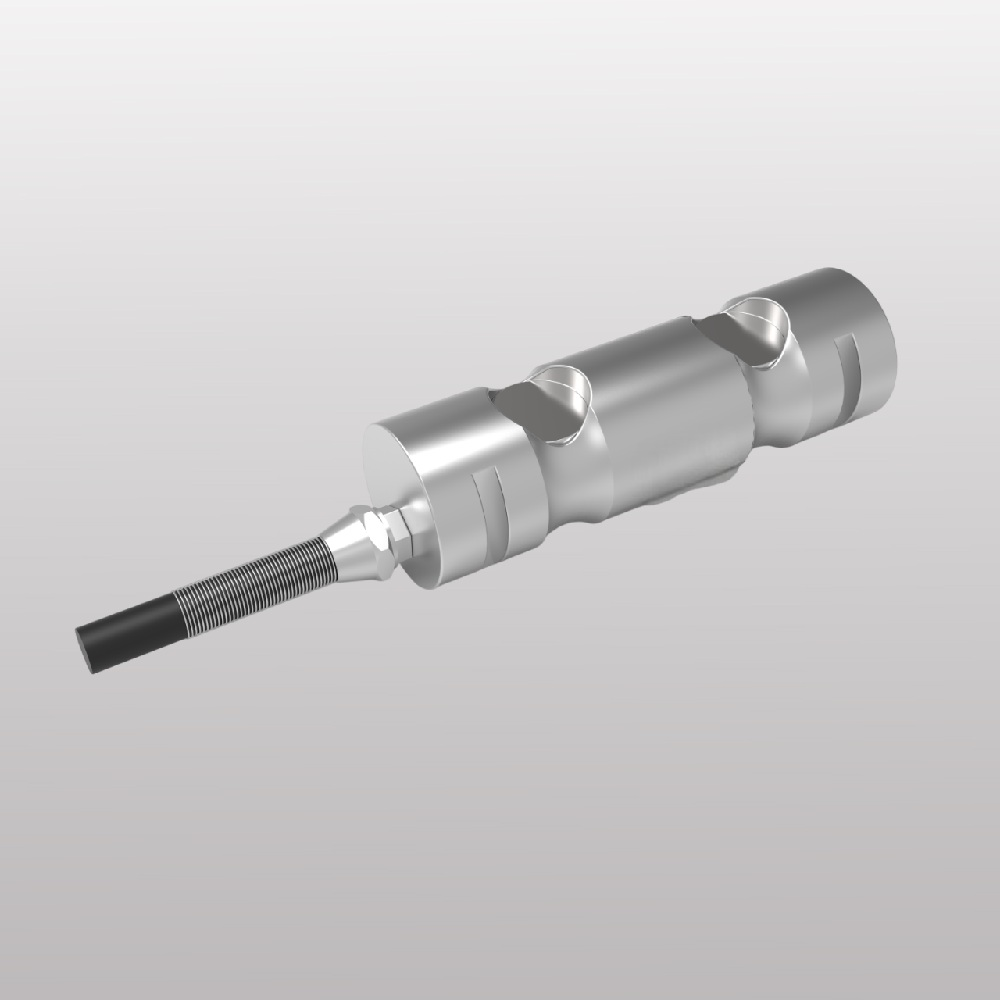

- Rotary Torque Sensors – Our rotary torque sensors are designed to measure dynamic and static torque with unmatched accuracy. Our sensors are designed to operate at high rotational speeds with no loss of performance. We also employ wireless transmission of data, and hence the operators can have real-time torque readings without the constraints of the conventional wired setup.

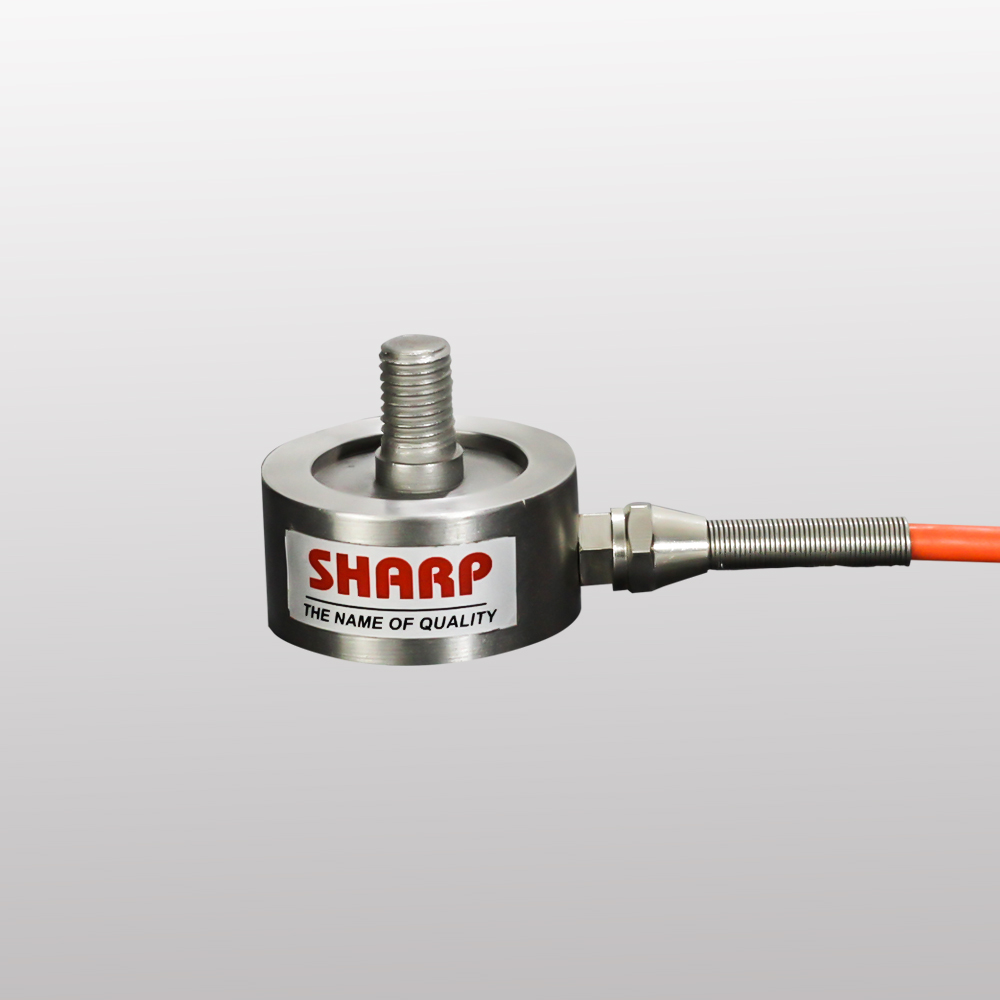

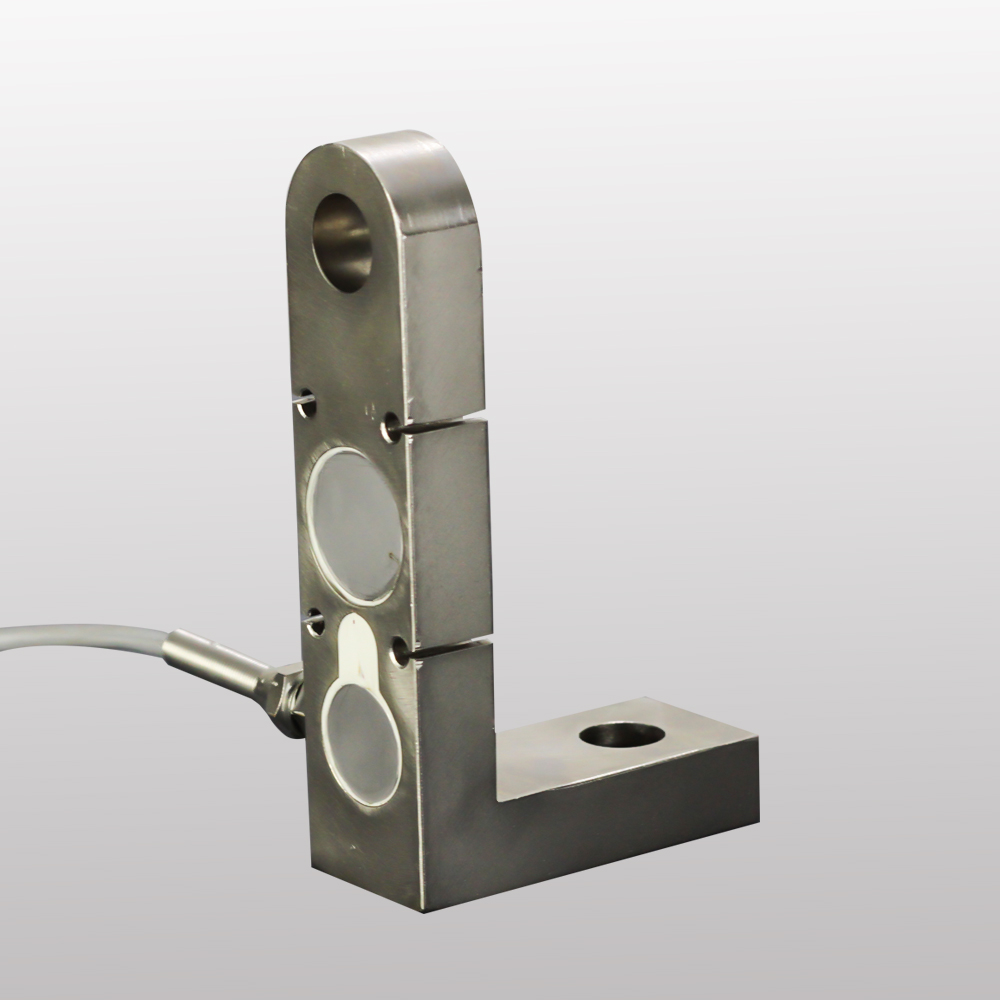

- Reaction Torque Sensors – Our reaction torque sensors are best used in cases where rotation is not employed but precise measurement of torque must be attained. They provide great stability and consistent results even during long work hours. We produce them from tough materials so that flexibility is never an issue under harsh industrial environments.

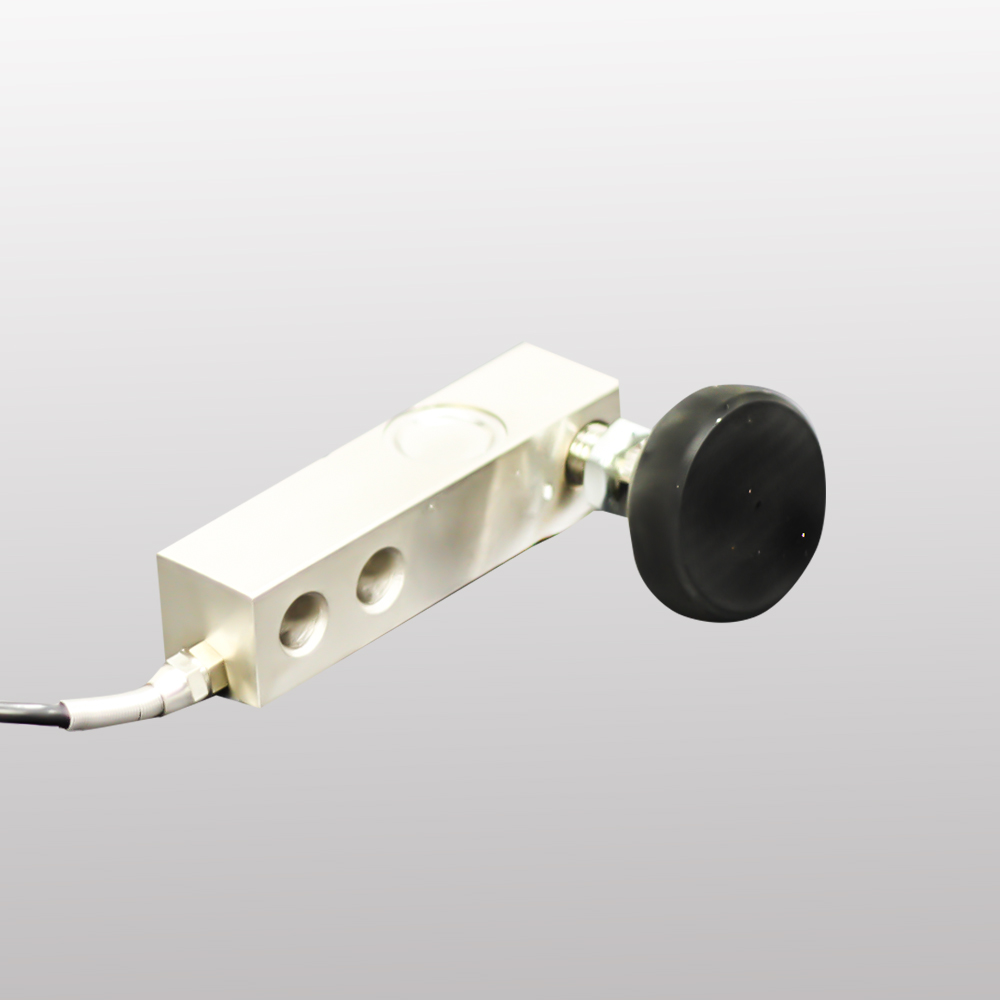

- Contactless Torque Sensors – We manufacture advanced contactless torque sensors based on non-contact signal transmission technology. This feature eliminates physical wear, which increases the working life of the sensor considerably. They are most ideally suited for constant use in machinery where maintenance downtime has to be reduced to the bare minimum.

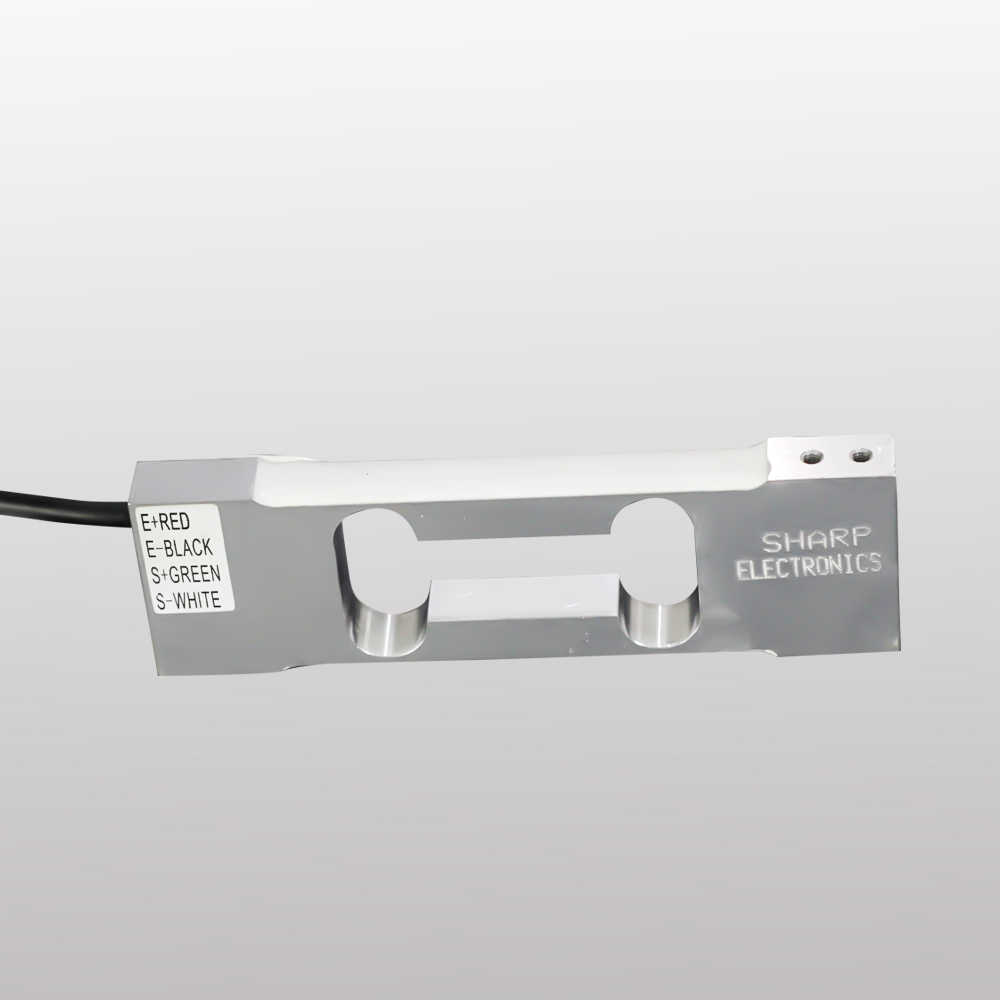

- Miniature Torque Sensors – We design miniaturized torque sensors with smaller sizes but sufficient accuracy. These are applied in robotics, precision equipment, and medical devices industries where there is limited space to conduct operations but accuracy are a priority. Their lightweight means it is easy to incorporate them without affecting the performance of equipment.

- Smart Torque Sensors – We produce smart torque sensors with IoT connectivity for intelligent monitoring solutions. The sensors facilitate predictive maintenance through real-time measurement of torque through internet-based platforms. With AI-driven analysis, industries benefit from faster and intelligent decision-making.

Technical Specifications

| Parameter | Specification |

|---|---|

| Sensor Type | Rotary, Non-contact Strain Gauge |

| Torque Range | 0.1 Nm – 500 Nm |

| Accuracy | ±0.05 % of Full Scale |

| Output Signal | ±5 V Analog / RS-485 Digital |

| Resolution | 0.01 Nm |

| Sampling Rate | 4 kHz |

| Operating Temperature | –20 °C to +85 °C |

| Overload Capacity | 150 % of Rated Torque |

| Shaft Diameter | 12 mm Solid Shaft |

Features of our Torque Sensor

Being one of the biggest Torque Sensor traders in Chennai, our all-types of Torque Sensors include new-tech formulations like:

- High-Resolution Measurement – We use top-quality strain gauge and magnetoelastic technology to provide our sensors with micro-level precision. This renders them extremely reliable for applications in which precise torque values with zero tolerance are required. The outcome is always a precise reading that ensures maximum overall process efficiency.

- Temperature Compensation – We integrate temperature compensation systems into our sensors such that they do not become inaccurate in very cold or hot temperatures. This guarantees the consistency of sensor performance regardless of climate. It also ensures the sensors function perfectly under external and warm industrial environments.

- Digital Signal Processing (DSP) – We use the art of DSP to deliver faster and noise-free data output. This allows operators to have clean, uninterrupted measurements for torque. It is especially useful in high-speed automatic systems where accuracy in milliseconds is critical.

- Wireless & Bluetooth Connectivity – We possess sophisticated wireless and Bluetooth-enabled sensors with plug-and-play interoperability with Industry 4.0 networks. This obviates the need for complicated cabling and increases operational flexibility. This also enables remote monitoring, minimising on-site physical presence.

- Self-Diagnoses – We turn our sensors into automatic self-diagnosing devices capable of detecting performance faults by themselves. This technology alerts operators prior to possible malfunction so that they can react in time. It is applied to minimise downtime as well as prolong the lifespan of the equipment.

- Rugged Housing – We make the outer casing of our sensors out of rugged material so that they can withstand dust, water, and vibration. Because of their rugged construction, they are able to take heavy-duty industrial conditions without the performance being compromised. It makes the sensors operate smoothly for decades.

Benefits of our Torque Sensor

These are all kinds of new Torque Sensors in Chennai, which provide different kinds of benefits such as:

- Enhanced Operation Efficiency – We give operators real-time torque feedback sensors, which enable them to control the production processes with utmost accuracy. This ensures that the end-product is of enhanced quality and consistency. Our technology enables more cycles of production in a significantly shorter time with no compromise on precision.

- Fewer Down Times – We build sensors with predictive maintenance features which detect likely problems before the failure occurs. This reduces surprise downtime, enabling production lines to keep running. It also tames surprise repair expenses for our clients.

- Cost Savings – We design our sensors to be low maintenance and long-lasting. Less servicing and replacement in the long term result from this. Our customers enjoy improved return on investment as the sensors are durable enough to last longer.

- Universal Compatibility – We have produced torque sensors which are compatible with a vast range of machinery and industrial tools. It allows you to incorporate them without going through essential changes. It also means that our products can be used across different industries.

- Green Operations – Our goal is to create energy-efficient sensors that are less mechanically stressful. This leads to green manufacturing processes and reduced operation costs. Industry solutions that assist them in fulfilling their environmental regulation needs are provided by us.

- Data-Driven Decision Making – We provide AI-driven analytics in our sensors, and businesses can make operational strategy decisions based on precise torque data. It identifies efficiency opportunities and enhances the productivity of manufacturing. The data gathered also assists with long-term planning and innovation.

Applications of our Torque Sensor

As Torque Sensor exporters of India, all ranges of Torque Sensors we have have new features and are extensively used in many applications including:

- Automotive Sector – We provide torque sensors, which are absolutely essential for testing drivetrain systems, gearboxes, and high-precision engines. Auto manufacturers can validate the reliability of products prior to vehicle launches using the sensors. The sensors are employed in R&D laboratories for developing the future of automotive technology.

- Aerospace Engineering – We supply aerospace-quality torque sensors employed for measuring forces in testing aircraft parts. Their accuracy allows optimal achievable performance and safety levels to be attained. They are preferred by commercial and defence aerospace operation companies.

- Robotics & Automation – We have robotic arm and automated assembly line torque sensors, which provide precise movement control. This helps in maintaining uniform product assembly without faults. They are best utilised in high-speed manufacturing plants where minor discrepancies can lead to faults.

- Renewable Energy Industry – We manufacture torque sensors for windmills to measure performance and efficiency. Precise measurement of torque ensures maximum energy returns and averts mechanical failure. The technology forms part of the global transition to cleaner forms of energy.

- Medical Equipment – We produce torque sensors that serve a key role in surgical equipment, prosthetic devices, and diagnostic equipment. Their precision level ensures patient safety through accurate medical procedures. We practice strict quality control to achieve regulatory requirements of the healthcare sector.

Sharp Electronics is well-known Torque Sensor manufacturers, suppliers, exporters, dealers, traders, and distributors in Chennai. We strive to deliver torque sensing solutions that not only measure accurately but also anticipate the evolving needs of emerging industries. Every sensor manufactured by us undergoes rigorous quality testing, advanced engineering validation, and compliance with international standards, thereby delivering unrivalled performance and reliability.

Our commitment is above and beyond the provision of products—our end-to-end technical assistance, customised solutions, and consulting knowledge assist buyers in selecting, implementing, and maintaining optimal torque sensing technology for their use case. With cutting-edge design, IoT-enabled monitoring, and predictive maintenance capabilities, we empower organisations to work with greater efficiency, precision, and confidence. Contact us today for more information!